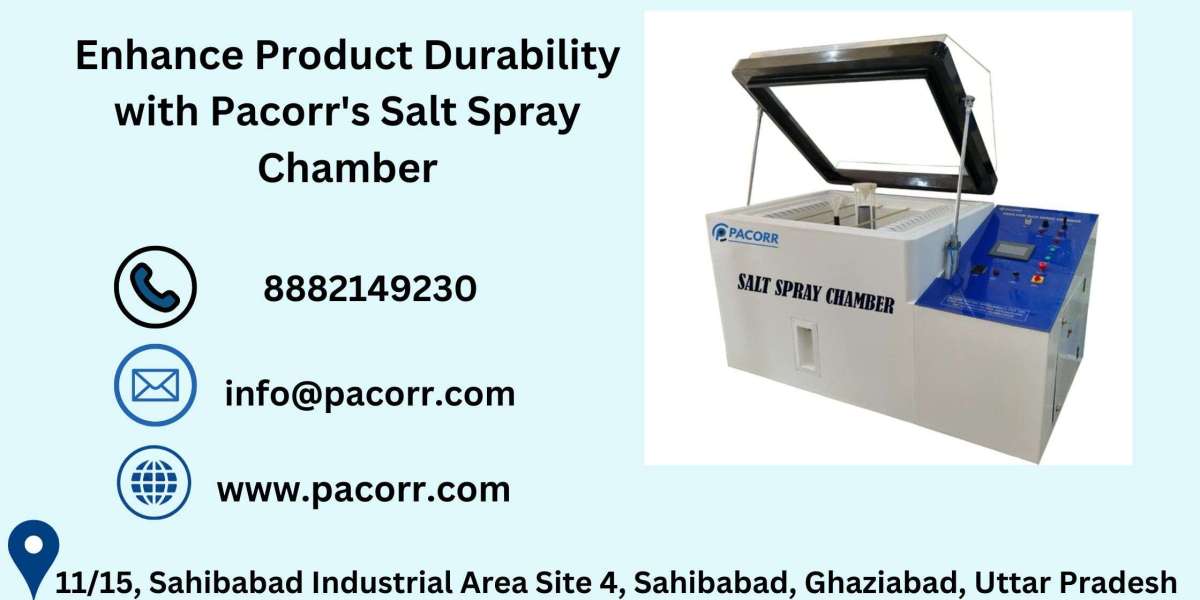

Enhance Corrosion Resistance Testing with Pacorr’s Salt Spray Chamber

Introduction

Corrosion is one of the primary challenges faced by manufacturers across industries. It significantly affects the longevity and quality of products, especially in sectors like automotive, aerospace, and construction, where metal components are critical. To combat corrosion effectively, reliable testing methods are essential, and this is where the Salt Spray Chamber offered by pacorr.com plays a vital role.

What is a Salt Spray Chamber?

The Salt Spray Test Chamber, also known as a corrosion test chamber, is a specialized testing instrument designed to simulate and accelerate corrosive conditions in a controlled environment. It exposes products to a saline mist or fog to evaluate their resistance to corrosion, enabling manufacturers to predict the durability and lifespan of their products in real-world environments.

Key Features of Pacorr’s Salt Spray Chamber

- High-Quality Construction: Built with robust materials to ensure consistent performance and durability.

- Advanced Control Systems: Equipped with user-friendly interfaces and precise control mechanisms for accurate testing.

- Customization Options: Adjustable test durations, temperature settings, and saline solution concentrations to meet diverse testing requirements.

- Compliance with Standards: Designed to adhere to international standards such as ASTM B117, ISO 9227, and JIS Z 2371 for reliable and repeatable results.

Applications of the Salt Spray Chamber

Pacorr’s Salt Spray Chamber serves a wide range of industries, including:

- Automotive: Testing the corrosion resistance of automotive parts like metal frames, bolts, and fasteners.

- Aerospace: Evaluating the performance of aircraft components exposed to extreme environmental conditions.

- Construction: Ensuring the durability of metallic structures and coatings used in buildings and infrastructure.

- Packaging: Assessing the protective quality of metal packaging materials.

Benefits of Using Pacorr’s Salt Spray Chamber

- Improved Product Quality: Helps manufacturers design products with better corrosion resistance.

- Cost Savings: Reduces the risk of product failures, saving costs on repairs, replacements, and warranty claims.

- Faster Time-to-Market: Enables rapid identification of weak points in product design, allowing for quicker improvements.

- Global Competitiveness: Ensures products meet international quality and performance standards.

Why Choose Pacorr for Salt Spray Chambers?

At pacorr.com, we take pride in delivering high-performance testing instruments tailored to industry needs. Our Salt Spray Chamber Testing combines cutting-edge technology with durability and precision to provide unmatched testing efficiency. With a focus on customer satisfaction, we ensure that our products meet stringent quality standards and offer excellent value for money.

Conclusion

Corrosion testing is critical for maintaining product quality and customer satisfaction. Pacorr’s Corrosion Test Chamber empowers manufacturers to assess and improve their products’ resistance to corrosion effectively. Explore the full range of testing instruments and discover how Pacorr can support your quality control processes.